(1) Power Controller Selection

When selecting a power control there are a number of decision criteria to consider:

– Process criteria

– Amperage and voltage to be controlled

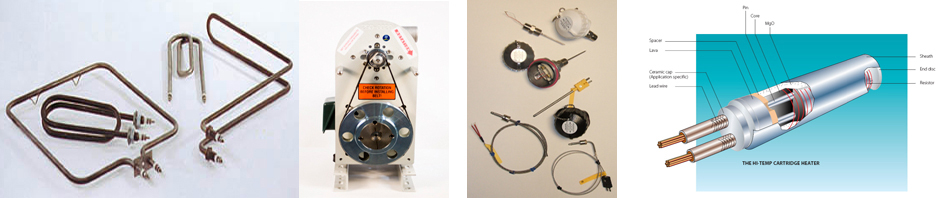

– Type and style of heater

– Response time of heater

– Nature of process (i.e. how tight does temperature variation need to be)

– Budget criteria

– Initial budget

– Operating budget (cost of maintenance, labor, power, downtime, wasted material cost from process failure)

– Cost of replacement (including potential clean-up and part availability)

(2) Purchase Cost vs. Performance

Different kinds of power controllers have different price and performance characteristics. In general, choices for power controllers are, in order of performance from low to high: Electro-mechanical, MDRs, SSRs, and SCRs. As amperage increases, performance differences become more pronounced with SCRs providing superior performance.

The same choices can be ranked (in order of increasing cost) Solid State Relays, Electro-mechanical Relays, Mercury Displacement Relays, and SCRs. As amperage increases, the cost difference narrows.

(3) Operating Costs

Operating costs for the power control include replacement costs, downtime for failures / maintenance, labor, and controller’s effect on the heaters. Each type of controller has an average life expectancy. For Electro-mechanical and MDRs, the life expectancy is measured in cycles. Both SSRs and SCRs are solid state devices, and life expectancy is more related to environmental factors (temperature) then cycles.

Electro-mechanical devices last, on average, 1,000,000 cycles. MDRs last, on average, between 1,000,000 and 10,000,000 cycles. Factors affecting the longevity of both controllers are: voltage being switched; ratio of line voltage to rated voltage; and number of cycles per hour.

(4) General Description of Types of Power Controllers

(a) Electro-Mechanical Relays/Contactors

The up-front cost for a simple relay is low on low power levels. As the power level goes up, the price rises. The mechanical relays will wear out (either mechanically or electrically) after a number of cycles. Labor costs and production down time to change a failure (in addition to wasted material caused by a run-away process) are often overlooked when selecting this type of contactor as primary switching device. Since cycle rates will affect life expectancy, slower cycle times result in poor control of a sensitive process.

Mechanical relays are often used as a safety device because of the complete mechanical break in the electrical circuit, whereas solid state units are subject to leakage current. When used in this way, electro-mechanical relays are not subjected to high cycle rates.

(i) Understanding Electro-Mechanical Relays

Electro-mechanical relays are specified by the following: number of poles, rated voltage, rated amperage, and coil specifications. The coil activates the switch, which physically engages the contacts. When the coil is de-energized, the contacts disengage. Load characteristics (voltage / amperage) differ by manufacturer. Controller switches line voltage, resulting in either full line voltage or nothing to the heaters. Coils can be either VDC or VAC. Coils are typically activated by a temperature control with a relay output.

(ii) When to use Electro-Mechanical Relays

When a mechanical break in the power circuit is desirable. When heaters will operate at full power continuously (relay is used as an on/off switch rather than constantly controlling process power).

(b) Mercury Displacement Relays (MDRs)

The up-front cost of a mercury displacement relay, or MDR, is low at low power. MDRs can cycle faster than a mechanical relay, and will not burn out as quickly since there is no contact wear. MDRs have to be mounted in a specific orientation.

MDRs can explode if overheated (due to cycling too fast or overpowered). Explosions result in a hazardous material problem (mercury). In addition, disposal of worn out contactors can be expensive (hazardous material: mercury). Control is still poor compared with solid state devices. Heaters still receive full line voltage on each cycle.

(i) Understanding Mercury Displacement Relays

2) MDRs use mercury as a contact material instead of metal contacts (such as found in electro-mechanical relays). Selection information is: voltage, amperage, number of poles and coil specifications. Because the mercury is liquid, MDRs can cycle faster and will last for more cycles than electro-mechanical relays. Load characteristics (voltage / amperage) differ by manufacturer. Controller switches line voltage, resulting in either full line voltage or nothing to the heaters. Coils can either be VDC or VAC. Coils are typically activated by a temperature control with a relay output.

(i) When to use Mercury Displacement Relays

When a mechanical break in the power circuit is desirable. When cycling of heater control is slow (few on/off cycles per time unit). When potential hazardous material cleanup / disposal is not a concern. When heaters and processes are slow responding so relatively long full power / no power cycles do not adversely affect processes or heater performance.

(b) Solid State Relays (SSRs)

The cost of low amperage Solid State Relays is low. There are several additional cost factors associated SSR’s. SSRs generate heat and should have heat sinks to operate at rated amperage / voltage. MOV’s and fuses needed for protection against electrical shorts and spikes are additional costs. Single surge current and voltage spike ratings are not as strong as an SCR. SSRs can cycle faster deliver better performance than mechanical devices. SSR’s only turn voltage on or off, process and heaters still see full voltage / no voltage.

(i) Understanding Solid State Relays

SSRs are solid state devices which control power by switching on and off at the zero cross point. SSRs cycle faster and last longer (provided they are fused and protected from over temperature) than either Electro-mechanical relays or MDRs. Information necessary to size a SSR for an application is line voltage, amperage, 1 or 3 phase, and input voltage. Controller switches line voltage, resulting in either full line voltage or nothing to the heaters. Input voltage is typically either VAC or VDC. Because SSRs are capable of faster cycle times pulsed VDC is the normal input for these switches. The pulsed VDC control input is generated by a temperature controller with a solid state DC output. Cycle time is normally limited by the temperature controller output limitations. Pulsed low voltage DC output allows for high cycle rates and easier wiring.

(ii) When to use Solid State Relays

When working with low amperage loads. When fast cycle times are important. When initial cost is an overriding consideration. When process / heaters respond more slowly than the SSR (as driven by the temperature controller) can cycle.

(c) Silicon Controlled Rectifiers (SCRs)

Costs of SCRs are higher at low power, but level out with other methods as amperage increases. SCRs should be installed with fast acting semi-conductor fuses. When completed with MOV’s and DV/DT protection for line noise and voltage spikes, an SCR control can operate for decades. There is no routine maintenance to carry out. The level of control that can be achieved with an SCR is unattainable with any other device. Phase angle control offers 0.08 second response times. Heater life can be extended by 7 times. Power to heaters is infinitely variable. Soft Start, Current Limit and Voltage Limit Options give advantages for controlling heaters. Soft Start allows the use of high inrush heaters. Current Limit gives control of high temperature elements for furnaces. Voltage Limit prevents temperature overshoot. Peak power can be reduced, saving utility costs.

(i) Understanding Silicon Controlled Rectifiers

A silicon controlled rectifier (SCR) is a solid state switching device which can provide fast, infinitely variable proportional control of electric power. Not only does this give maximum control of your heat process, but it can extend heater life as compared to other control methods. Since the SCR is solid state, it can cycle on and off over a billion times, if properly used. SCRs can be used in the following ways:

On/Off Control works like a mechanical or mercury relay. When the SCR is on it fires full voltage into the heater until the command signal turns it off.

Phase Angle Fired controls proportionally turn on a percentage of each power cycle. This gives smooth, infinitely variable application of power to the heaters. Phase Angle Fired SCRs provide the most precise control of heaters, quickest response to load changes, and maximum heater life. Only Phase Angle Fired SCRs can have options such as Voltage Limit, Soft Start, and Current Limit.

Zero Voltage Cross Switched controls proportionally turn on and off each full power cycle. The SCR controls power by varying the number of AC power line cycles. A variable time base determines the optimum number of cycles to be turned on or off. The switching is done at fractions of a second during the zero voltage crossing of the power line cycles. For fast responding elements (e.g. a T3 infrared heating element), the element may flicker. For heaters with greater mass, temperature can be controlled within very tight tolerances.

Normally, SCRs are controller by a linear input from a temperature controller. This input can be 0-20mA, 4-20mA, 0-5 VDC, or 0-10VDC.

(ii) When to use Silicon Controlled Rectifiers

When working with high amperage loads. When process depends on precise temperature tolerances. When working with fast response heaters and processes. When reliability is critical. When overall operating costs are more important than initial controller cost.